Description

DESCRIPTION

TECHNICAL DATA

VIDEO

SEND A MESSAGE

HIGHLIGHTS

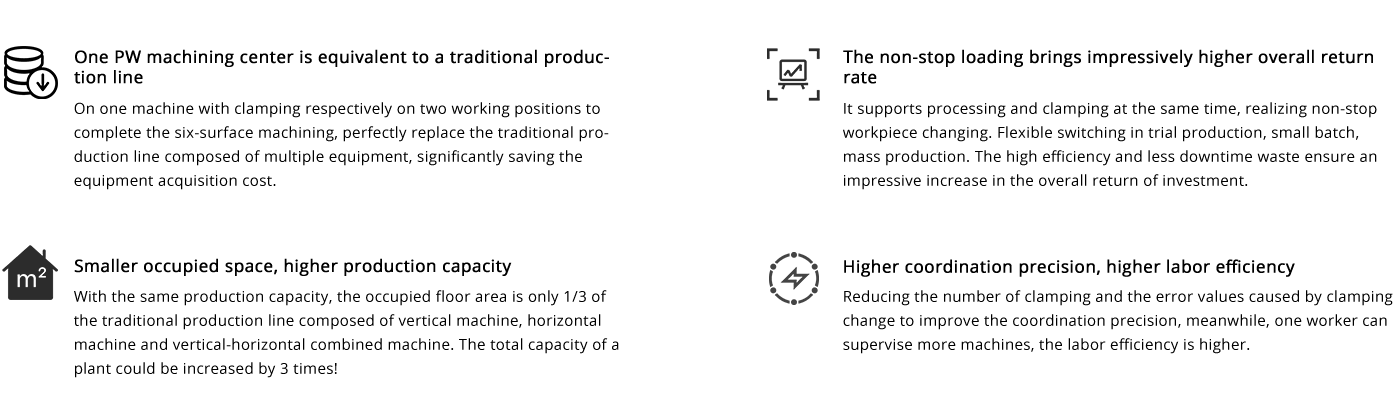

Comparing with the traditional production line, the PWM series is advantaged in the following aspects:

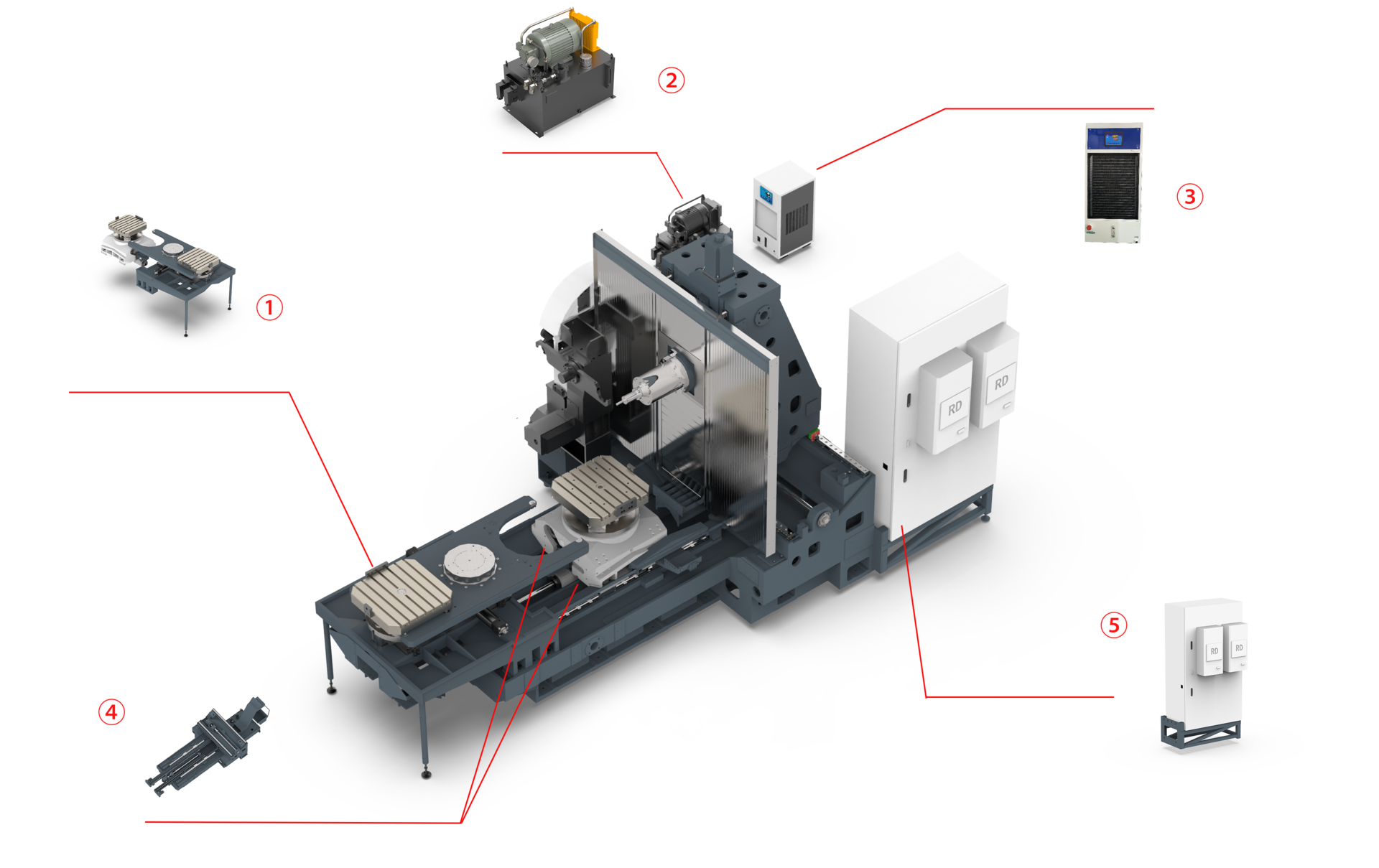

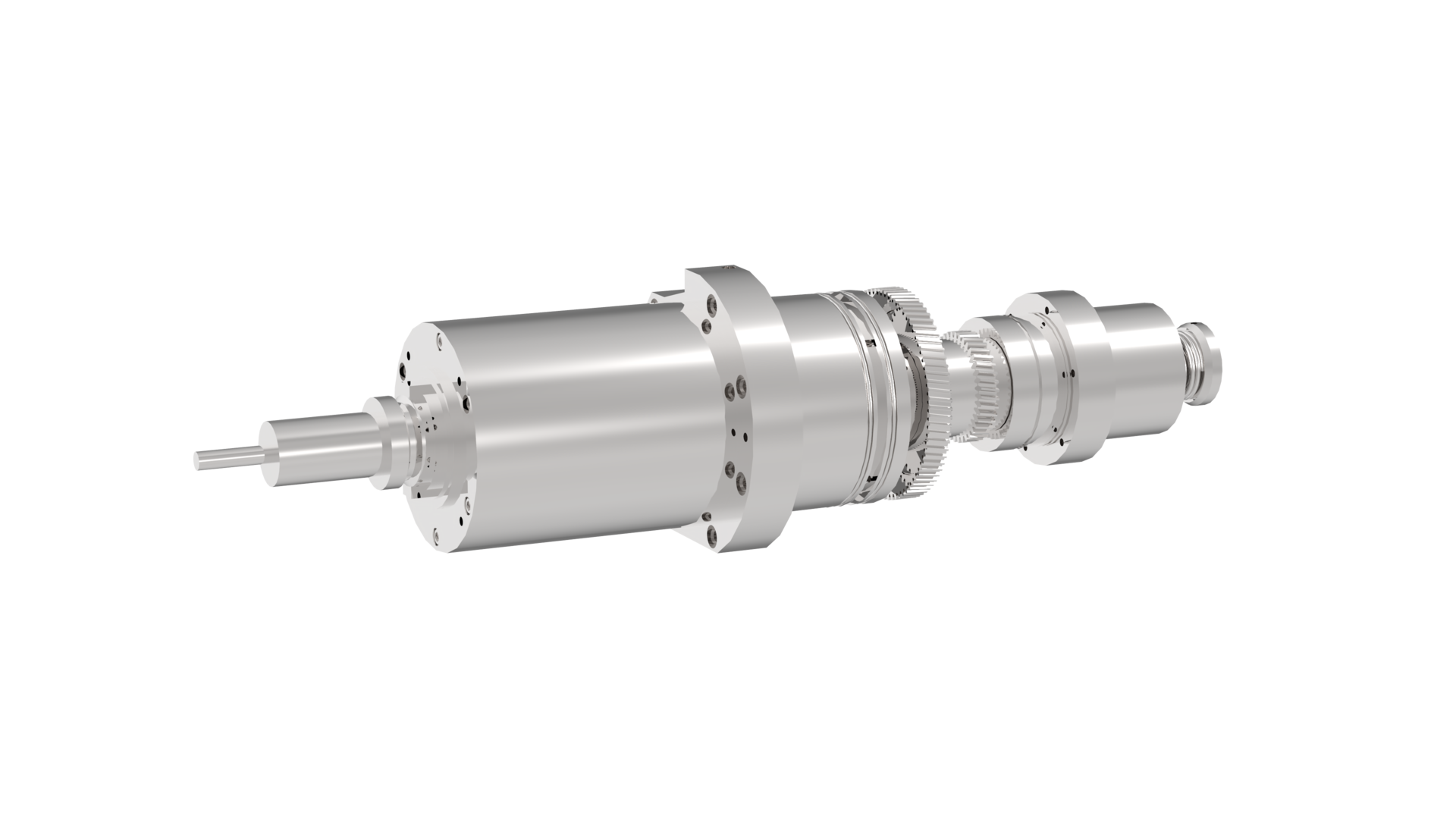

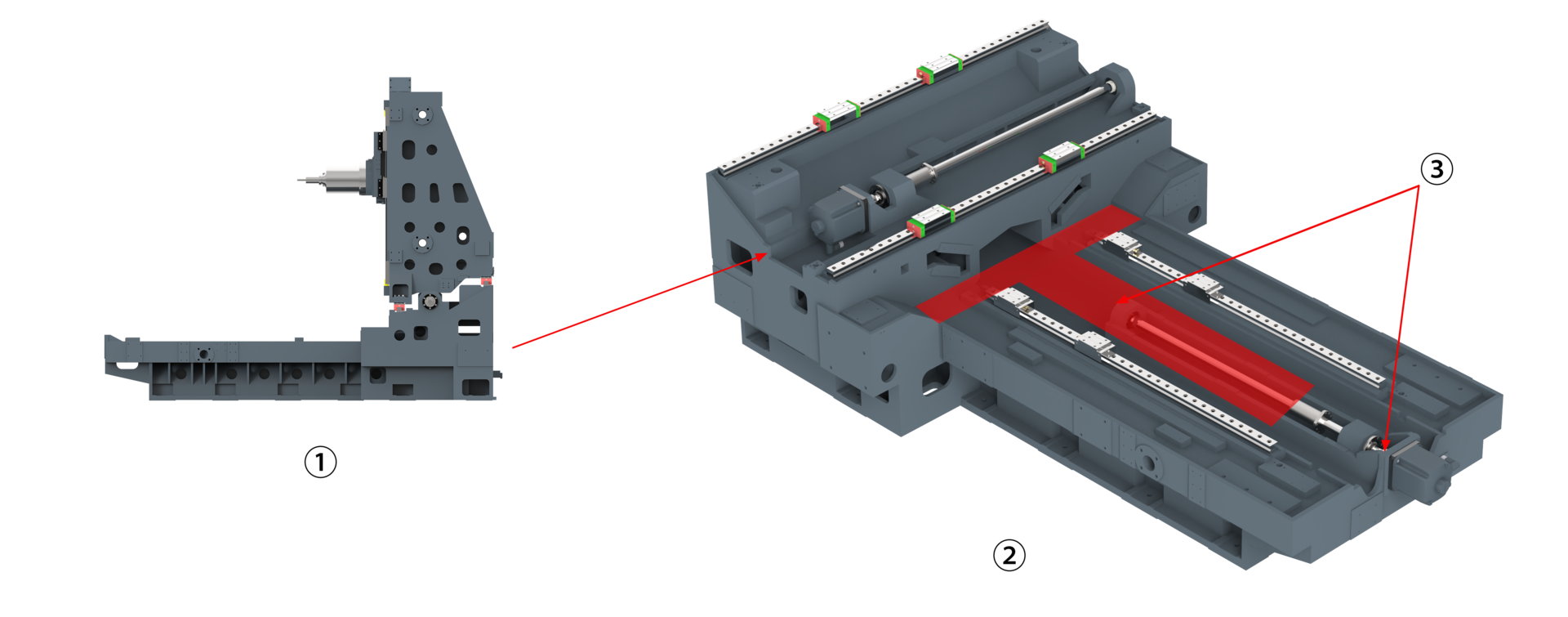

Integral machine bed ensures high rigidity and high dynamic response capability

|

|

|

The powerful processing capability

|

Optimal configuration and layout, to ensure the convenience and efficiency of using the machine.

- Exchangeable rotary table, exhcanging time is shorter

- Hydraulic station

- Oil cooler

- The Oil cooler and hydraulic station are arranged independently from the main machine for easy maintenance.

- The electrical cabinet is bolted to the bed via a bracket for easy lifting and transportation

- The chip convayer is located on both sides of the turntable, which is more convenient for chip removal.

VIDEO

TECHNICAL DATA

| Items | Unit | PWM-63II | PWM-80II | |

| Travel | X-axis | mm | 1000 | 1300 |

| Y-axis | mm | 900 | 1100 | |

| Z-axis | mm | 1000 | 1200 | |

| Spindle | Type | / | Mechanical | |

| Power (S1/S6) | kW | 17/20.4 | ||

| Torque (S1/S6) | N.m. | 870/1044 | ||

| Max. speed | rpm | 6000 | ||

| Taper | / | BT50 | ||

| Feedrates | Rapid on X/Y/Z | m/min | 24 | |

| X/Y/Z Cutting Feed Rate | m/min | 15 | ||

| Tool Magazine | Type | / | Chain type | |

| Capacity | pcs. | 40 | ||

| Tool-to-tool time | sec | 5.5 | ||

| Dimension | Machine Height | mm | 3450 | 4000 |

| Covering Area | mm | 7500*3950 | 7800*4800 | |

| Machine Weight | t | 19 | 25 | |