Description

DESCRIPTION

| World-Class Components for High Precision

• Control system uses Fanuc/Siemens/Mitsubishi. It can meet complex processing requirements, achieves automatic and continuous milling, boring, drilling, reaming, tapping in one clamp. • The three-axis bearing adopts P4 class of Japanese NSK/NACHI. • The triaxial axis screw adopts Taiwan HIWIN C3 class. • The main electrical components adopt French Schneider. |

|

|

|

BT40 spindle provides high precision and high speed processing

The 12,000 rpm spindle adopts an oversized motor and is driven by a direct drive servo motor with brake. Stable and reliable for high-speed milling or drilling. Constant temperature design, low temperature rise, small thermal deformation, stable processing performance. An additional function of independent water irrigation is possible, which effectively extends the service life of the tool. |

| 2-second high-speed tool change 2-second tool change time reduces downtime and improves machining efficiency. The disc type tool magazine can store 24 tools, providing excellent flexibility in operation. |  |

BASIC INFORMATION

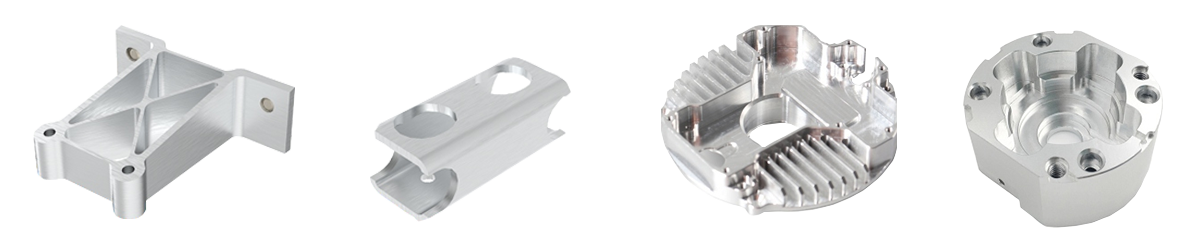

• The machine integrates milling, drilling and tapping functions

• Processing of metal profiles of various lengths such as aluminum, steel, copper and non-metallic materials.

• Widely used in railway transport industry, aerospace industry, military equipment, guide linear modules, etc.

TECHNICAL DATA

| Options | Unit | PL855 | PL1165 | PL1375 | |

| Move | X-axis | mm | 800 | 1100 | 1300 |

| Y-axis | mm | 550 | 650 | 750 | |

| Z-axis | mm | 550 | 600 | 600 | |

| Distance from spindle to table surface | mm | 120-670 | 120-720 | 120-720 | |

| Table | Size (Length*Width) | mm | 1000×550 | 1200×600 | 1300×700 |

| Max. load | Kg/m² | 500 | 700 | 800 | |

| T-Slots (Number/Width/Center Distance) | mm | 5-*18T*90 | 5-*18T*100 | 7-*18T*100 | |

| Spindle | Type | / | Mechanical | Mechanical | Mechanical |

| Power (S1/S6) | kW | 7.5/15 | 11/18.5 | 11/18.5 | |

| Torque (S1/S6) | Nm | 35.5/95.5 | 52.5/118 | 52.5/118 | |

| Max. speed | rpm | 12000 | 12000 | 12000 | |

| Cone | / | BT40/SK40/CAT40 | BT40/SK40/CAT40 | BT40/SK40/CAT40 | |

| Feed rate | Fast X/Y/Z | m/min | 48/48/48 | 36/36/36 | 36/36/36 |

| Cutting speed X/Y/Z | m/min | 1~10000 | |||

| Tool shop | Type | / | Disc type | ||

| Capacity | PC. | 24 | |||

| Tool change time | sec | 2 | |||

| Dimensions | Machine height | mm | 2600 | 2700 | 3000 |

| Coverage area | mm | 2800*2600 | 2980*3120 | 3340*3160 | |

| Machine weight | kg | 5500 | 7000 | 7500 | |

VIDEO